Well, with all of the fairing finally done on the outside it was time to start getting it painted. I began inside, painting my way out from the bow. The paintwork was a long tiresome process that fortunately yielded a nice result in the end.

In order to paint the interior I had to do several days of sanding to get all of the fillets smoothed out and grind off any excess epoxy from the assembly process. This was tedious work as by now I had quite had my fill of sanding, but there was more to come.

It was at this point that I decided to drill the holes for the keel bolts as the centerline markings were still visible on the oak keel beams making the locating of the holes much easier.

I followed the example of previous builders and over drilled the 12mm bolt holes out to 15mm. I then used thickened epoxy to glue in fiberglass tubes with a 15mm o.d. and a 12mm i.d. This not only insulates the white oak from any possible water intrusion, it also makes the holes nearly crush proof with the tubes in that orientation.

Using an old mag drill just set and balanced on the beams I was able to drill the holes nice and straight. Afterwards I taped the outside of the hull and inserted the tubes. Measured the length, cut, and glued them in place.

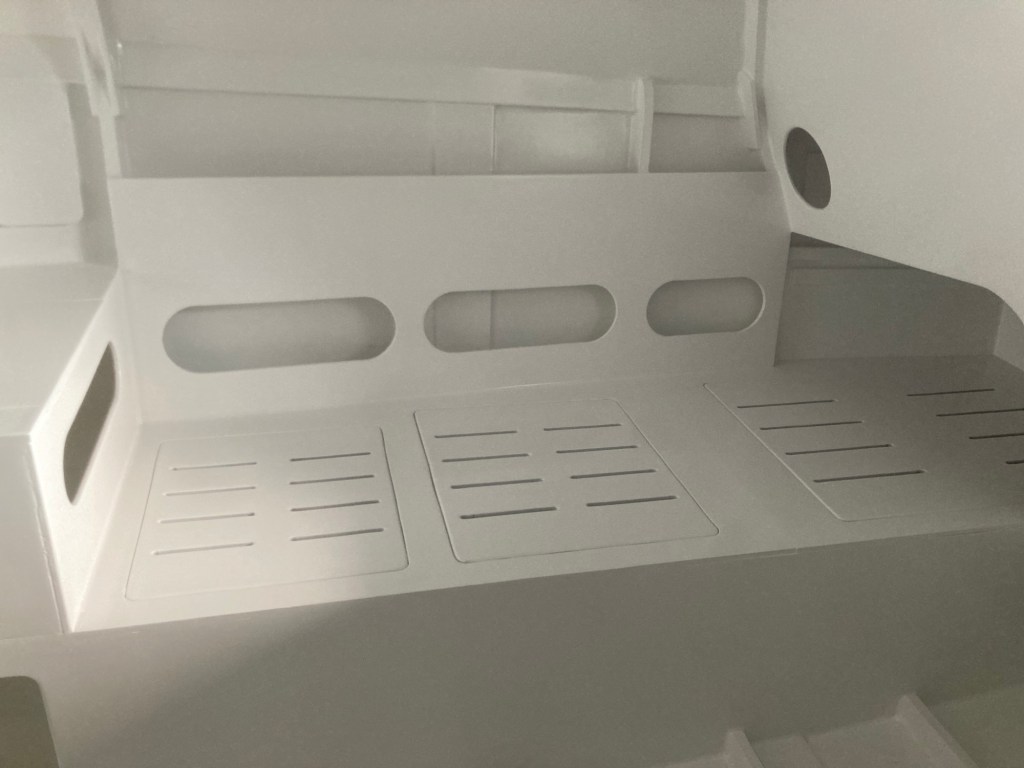

To prep the interior for paint I sanded everything inside with 80 grit. Then I sprayed in two coats of Alexseal 302 high build primer. I sanded that with 180 grit and then sprayed in two coats of the Alexseal 442 finish primer. Sanded that with 320 grit and sprayed in two coats of Alexseal 501 Snow White topcoat. Sanded that with 400 grit and then sprayed in the final layer of 501 topcoat.

The Alexseal 501 topcoats are a very high gloss paint system. I did not really want to have a high gloss interior as I feel it is a little too harsh on the eyes. To help with this I used the Alexseal Flattening Additive to give the surface a semi-gloss finish. This additive is mixed into the paint before it is catalyzed and gives it varying degrees of matte depending on the mixed proportions.

With the final topcoat done I gave it a couple of days to cure nice and hard. I then wet sanded everything with 800 grit, 1000 grit, 2000 grit, and finally polish with light compound on the buffing wheel. The result was a nice, semi-gloss, bullet hard surface that should last for years to come.

Up next the equally painstaking process of painting the exterior. Thanks for reading!